User interface

(→Continue conditions) |

(→Continue conditions) |

||

| Line 86: | Line 86: | ||

vel=0.5 : dist=0.4 | vel=0.5 : dist=0.4 | ||

| − | Example: drive 0.2m | + | Example: drive 0.2m and then turn 45 deg CCW (counterclockwise) and then 45 deg CW (clockwise), and repeat this 3 times with a goto that goes to label=6 two times. |

| − | vel= | + | vel=0.2,acc=2,label=6: dist=0.2 |

tr=0.1:turn=45 | tr=0.1:turn=45 | ||

| − | tr= | + | tr=0.1:turn=-45 |

goto=6 : count=2 | goto=6 : count=2 | ||

vel=0:time=0.5 | vel=0:time=0.5 | ||

Revision as of 16:40, 23 January 2016

Contents |

Screen dumps

The user interface can configure and run the robot, as well as inspecting almost all values on the robot. Written in python using Qt GUI library.

The interface looks like on figures below.

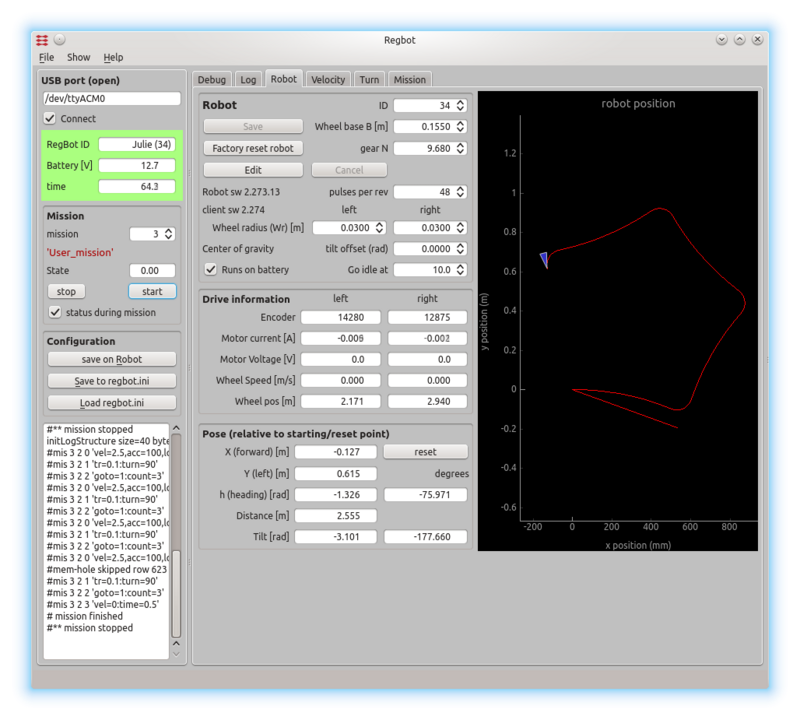

Figure 1. The general settings for the robot. The left panel is the general connection status and space for som messages from the robot. The central tab is mostly for configuration of the robot and some sensor and calculated values like pose and tilt. To the right is a fast graph of the last mission.

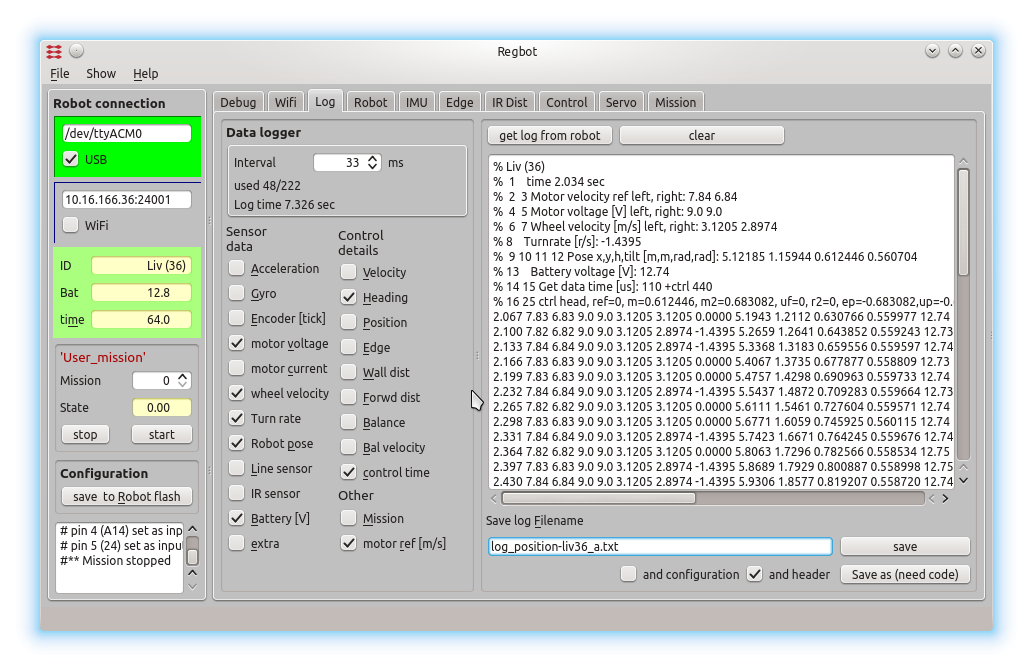

Figure 2. The data logging options. A number of sensor values and interface points in the robot software can be logged. The window text window shows loaded data from a mission. The log format is designed to be directly compatible with the 'load' function in MATLAB.

The GUI allows to make step responses for velocity and turn (and most of the other controllers). The step response is recorded in a buffer on the robot and is fetched in a MATLAB style file (as shown). Interface points that are recorded can be switched on and off to better utilize the limited buffer size on the robot (35kBytes).

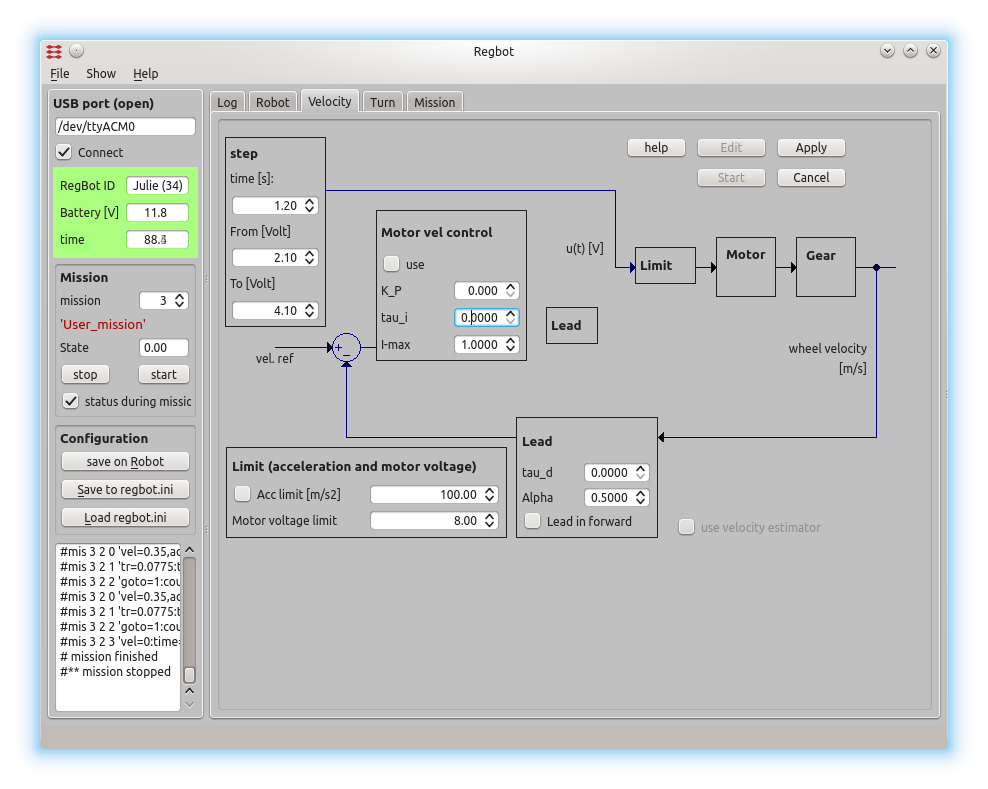

Figure 3. This is a page to make a step response and insert controller values for velocity control. The same controller is used for both wheels.

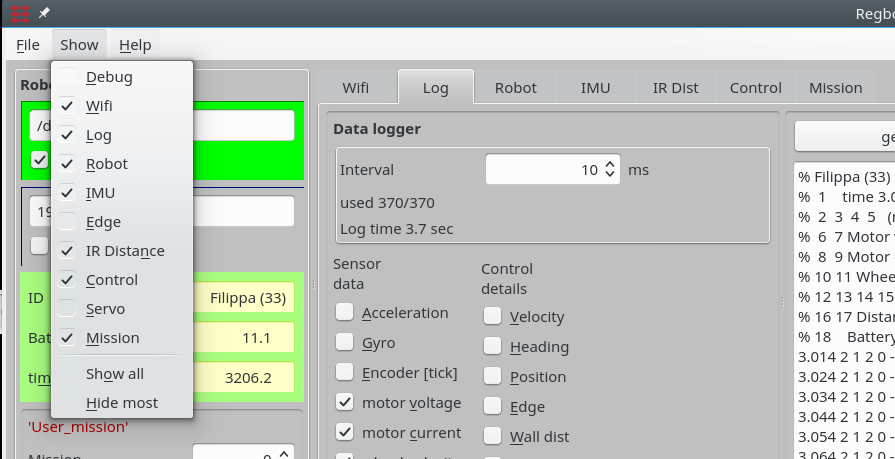

Figure 4. Other tab pages are available from the "show" menu.

Mission

Mission specification consist of mission lines, each line consist of two (lower case) parts divided by ':'

drive values : continue conditions (conditions are OR'ed)

e.g.:

vel=-0.2, acc=3.0 : dist=1, time=12

Drive backwards at a speed of 0.2m/s, accelerate with 3m/s2 for 1 meter (or max 12 seconds)

Drive values

- VEL is velocity in m/s - positive is forward, 0=stop. uses last value if omitted.

- ACC is acceleration limit in m/s2. Uses last value if omitted.

- TR is turnradius in metre - positive, 0 is turn on the spot. straight if omitted

- LOG is log interval in milliseconds. Once started it continues until buffer is full.

- BAL is balancing, uses last value if omitted.

- LABEL is a label number that can be used by GOTO.

- GOTO is a jump to the label number given. This can be limited to COUNT

Line-sensor

If a line sensor is installed, then the following should work too:

- LINER is following Right side of line at -2..2 (in cm), positive is right

- LINEL is following Left side of line at -2..2 (in cm), positive is right

- WHITE set to 1 if follow-line tape is white, else 0

Distance sensor

If IR distance sensors are installed, then these should work:

- IRSENSOR is IR-sensor to use (1 is distance to a wall, and 2 is distance in front).

- IRDist is IR-distance to hold.

Continue conditions

':' is separation of parameters and continue condition.

- DIST is driven distance in this mission line - positive meters

- TURN is angle turned in this mission line - degrees, positive is CCV

- TIME is max time in this mission line - positive seconds

- COUNT is used with GOTO and GOTO will be ignored, if this line is executed more than this count

Example: Drive 0.2m then turn 30 deg to the right (turn radius=0, but will be more with acceleration beeing only 1m/s2) then drive another 0.4m at a higher speed

vel=0.2,acc=1 : dist=0.2 tr=0 : turn = -30 vel=0.5 : dist=0.4

Example: drive 0.2m and then turn 45 deg CCW (counterclockwise) and then 45 deg CW (clockwise), and repeat this 3 times with a goto that goes to label=6 two times.

vel=0.2,acc=2,label=6: dist=0.2 tr=0.1:turn=45 tr=0.1:turn=-45 goto=6 : count=2 vel=0:time=0.5

Line sensor

This section is valid if a line sensor is installed and calibrated. Use "Edge" tab for calibration (put edge sensor "ON" and on a dark background and press "Calibrate no reflection" and then on a bright background and press "Calibrate white reflection").

- XB, XW is test for crossing black/white line, value is 0..20, 0 is true on no crossing, 1..20 is confidence in crossing (20 is highest)

Example: Drive until a crossing black line is found or 2.5m is driven, then continue until the crossing line is gone (reached other side of line) and stop

vel=0.2, log=5, acc=2: xb>16, dist=2.5 :xb < 4,dist=0.2 vel=0:time=0.1

Example: Follow left edge of a white line until it ends (or after 1m), then stop

vel=0.3,acc=2,log=10: linel=0,white=1:xb>5,dist=1 vel=0:time=0.5

Distance sensor

- LV is test for valid line 0=true for no valid line, 1=true for valid line. IR1, IR2 is test for distance measured by IR sensor. TILT is test for tilt angle (0 is balance point)

Examples

e.g.: drive-turn-drive-turn at 20cm/s:

vel=0.2, acc=1.5 : dist = 0.5, time=5 tr=0.15 : turn=90 : dist = 0.5 tr=0.15 : turn=90 vel=0 : time=1

e.g. wait 5 seconds

vel=0 : time=5

Save

Transfer the mission to the robot RAM by pressing "Save" (top right), the mission will be lost by a reboot or power off, unless saved on robot!

Save the mission on the robot flash memory (EE-prom) by pressing "save on Robot" (left panel). NB! The space is limited (about 100 lines)!

The mission can also be saved in a text-file useing the bottom right save button