Regbot calibration

From Rsewiki

(Difference between revisions)

(→Calibration) |

(→Encoder) |

||

| Line 21: | Line 21: | ||

Figure 2. Calibration the encoder. The graph shows for all 48 encoder tics the time between the tics at constant velocity. Ideally it should be a straight line. | Figure 2. Calibration the encoder. The graph shows for all 48 encoder tics the time between the tics at constant velocity. Ideally it should be a straight line. | ||

| − | * To calibrate | + | * To calibrate tick both "Get raw data regulary" and "Run motor at 3V" (wheels away from floor). |

This will show some rather uneven lines in the plot. | This will show some rather uneven lines in the plot. | ||

* press the "Do calibration" button, once the velocity is stable. | * press the "Do calibration" button, once the velocity is stable. | ||

This should make the calibrated lines more straight. | This should make the calibrated lines more straight. | ||

| + | * Tick also the "Use calibration" (to the right) to use the calibrated values. If this is ticked and the calibration is out of sync, then it probably is worse than no calibration. | ||

* NB! the calibration will only work as long as all encoder tics are counted, i.e. not after a reboot. | * NB! the calibration will only work as long as all encoder tics are counted, i.e. not after a reboot. | ||

Revision as of 09:55, 9 February 2019

Calibration

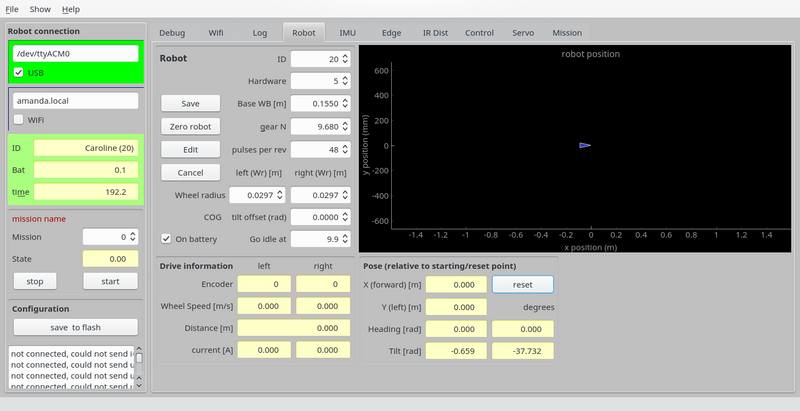

In the REGBOt GUI, the "robot" pane has the basic configuration

Figure 1. Basic robot settings.

- "Base WB [m]" is the distance between driving wheels. This is important for heading calculation and turning.

- "gear N" is gear reduction - normally 9.68

- "pulses per rev" is encoder configuration - number of pulses for one motor revolution - normally 48.

- "wheel radius" is important for distance calculation, and a bit for velocity and turning.

- "COG tilt offset" is important when keeping balance, should be adjusted, so that "tilt" (lower right) is 0, when in balance (hand held).

Encoder

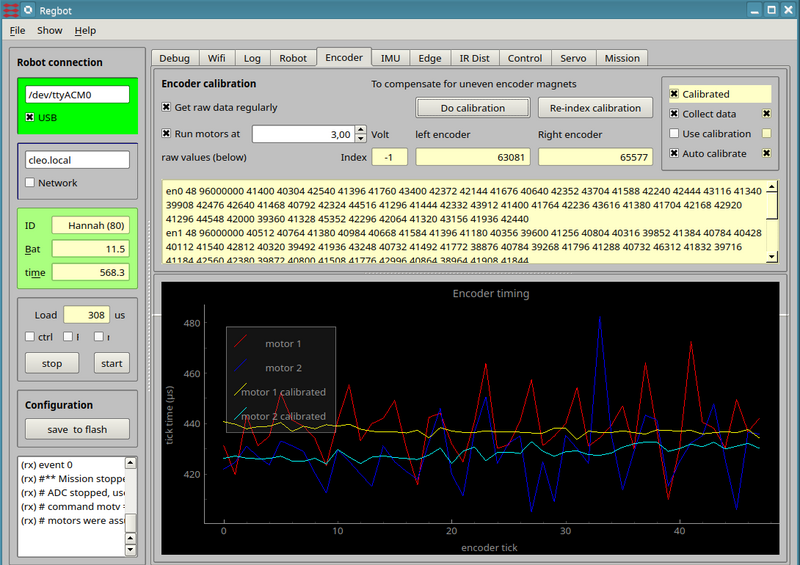

Encoder calibration attempt to compensate for the uneven sized magnets in the magnetic encoder.

Figure 2. Calibration the encoder. The graph shows for all 48 encoder tics the time between the tics at constant velocity. Ideally it should be a straight line.

- To calibrate tick both "Get raw data regulary" and "Run motor at 3V" (wheels away from floor).

This will show some rather uneven lines in the plot.

- press the "Do calibration" button, once the velocity is stable.

This should make the calibrated lines more straight.

- Tick also the "Use calibration" (to the right) to use the calibrated values. If this is ticked and the calibration is out of sync, then it probably is worse than no calibration.

- NB! the calibration will only work as long as all encoder tics are counted, i.e. not after a reboot.