To do

From Rsewiki

(Difference between revisions)

(→Body) |

(→Foot) |

||

| (17 intermediate revisions by 2 users not shown) | |||

| Line 3: | Line 3: | ||

Possible improvements, design ideas and other suggestions. | Possible improvements, design ideas and other suggestions. | ||

| − | + | Back to [[Flexbot]] main page | |

| − | + | =Mechanics= | |

| − | + | ||

| − | + | [[Flexbot 3D print]] status | |

| + | |||

| + | == Foot == | ||

| + | |||

| + | Assembly order: | ||

| + | * Fix connection (motor-to-axle-mount) to wheel axle with 2x4mm short screws, before inserting into alu wheel-stear-mount | ||

| + | * Alu wheel-steer-mount (with 4 bearings), insert axle assembly (from above) and secure it with wheel-nut - and fasten with pinol | ||

| + | * Insert 5-6mm cylinder peace into turn bearings in wheel-steer-mount, and mount into steer-mount (non turning part) with 2x5mm screws and self-locking nuts. Make sure turn motion is OK. | ||

| + | * Assemble motor and motor-mount block with 4x3mm screws into motor - make sure that motor in upright orientation and motor-mount matches wheel-steer-mount orientation. | ||

| + | * Insert motor and motor-mount assembly into axle and fixate it to wheel-steer-mount with 2x3mm 50mm long screws and self locking nuts. | ||

| + | * Tighten motor axle into aluminum flex motor-to-axle and fix it in one end at a time - as possible. Try turn motor or wheel to verify smooth turning. | ||

| + | * Mount foot-base (big block) to steer-mount with 4x long self cutting screws | ||

| + | |||

| + | * for steering mount blocks on motor (with strip) and on foot-base (4xsmall self cutting screws) | ||

| + | * Mount Firgelli actuator for steering actuation with 2x 4mm 25-35mm long screws and self locking nuts. | ||

| + | |||

| + | [[File:foot+motor.png|400px]] | ||

| + | |||

| + | Front right wheel and foot part. | ||

====Motor and turn part==== | ====Motor and turn part==== | ||

| − | + | ||

| − | * Turn (king-pin) bolt should be 5mm, and with bigger cone for the screw. | + | (first number is priority, 1. is must, 2. is can maybe do without, 3. would be nice) |

| − | * Cut-out for motor, for raised ring on motor, should be bigger. | + | |

| + | * 2. Turn (king-pin) bolt should be 5mm, and with bigger cone for the screw. | ||

| + | * 3. Cut-out for motor (on face with motor axle), for raised ring on motor, should be bigger in diameter. | ||

====Big block==== | ====Big block==== | ||

| − | * | + | * 2. Make hole for motor driver cooling. |

| − | + | * 2. use higher temperature for orange PETG plastic print (165 degree, not 162) | |

| − | * | + | |

| − | + | ====Steering==== | |

| − | + | * 1. Mount block on foot do not allow full actuator movement | |

| + | * 2. Mount of Firgelli too sloppy, maybe a plastic adaptor in each end? | ||

| + | * 1. Mount block in foot end has too small screws, and may be too week. | ||

| − | + | ==Knee== | |

| − | + | ==Hip== | |

| − | + | ==Main body== | |

| − | + | =Electronics= | |

| − | + | ==Power== | |

* Main power 6-cell LiPo nominel 22.2V (between 20V and 28.5V) | * Main power 6-cell LiPo nominel 22.2V (between 20V and 28.5V) | ||

| − | + | ==Teensy== | |

* Teensy 3.2 and Teensy 3.5 for (first level) real time control loops | * Teensy 3.2 and Teensy 3.5 for (first level) real time control loops | ||

| − | + | ==Main PC== | |

* Look at a Intel Nuc | * Look at a Intel Nuc | ||

| − | + | ==Sensors== | |

| − | + | =Matlab Model= | |

| − | + | =Software= | |

| − | + | ==Communication== | |

| + | * Losing IMU i2c communication at knee | ||

| − | + | ==Control== | |

Latest revision as of 14:56, 8 June 2018

Flexbot design to do list

Possible improvements, design ideas and other suggestions.

Back to Flexbot main page

Contents |

[edit] Mechanics

Flexbot 3D print status

[edit] Foot

Assembly order:

- Fix connection (motor-to-axle-mount) to wheel axle with 2x4mm short screws, before inserting into alu wheel-stear-mount

- Alu wheel-steer-mount (with 4 bearings), insert axle assembly (from above) and secure it with wheel-nut - and fasten with pinol

- Insert 5-6mm cylinder peace into turn bearings in wheel-steer-mount, and mount into steer-mount (non turning part) with 2x5mm screws and self-locking nuts. Make sure turn motion is OK.

- Assemble motor and motor-mount block with 4x3mm screws into motor - make sure that motor in upright orientation and motor-mount matches wheel-steer-mount orientation.

- Insert motor and motor-mount assembly into axle and fixate it to wheel-steer-mount with 2x3mm 50mm long screws and self locking nuts.

- Tighten motor axle into aluminum flex motor-to-axle and fix it in one end at a time - as possible. Try turn motor or wheel to verify smooth turning.

- Mount foot-base (big block) to steer-mount with 4x long self cutting screws

- for steering mount blocks on motor (with strip) and on foot-base (4xsmall self cutting screws)

- Mount Firgelli actuator for steering actuation with 2x 4mm 25-35mm long screws and self locking nuts.

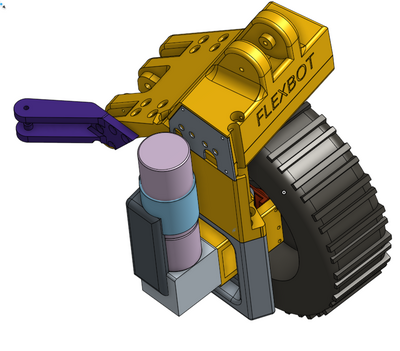

Front right wheel and foot part.

[edit] Motor and turn part

(first number is priority, 1. is must, 2. is can maybe do without, 3. would be nice)

- 2. Turn (king-pin) bolt should be 5mm, and with bigger cone for the screw.

- 3. Cut-out for motor (on face with motor axle), for raised ring on motor, should be bigger in diameter.

[edit] Big block

- 2. Make hole for motor driver cooling.

- 2. use higher temperature for orange PETG plastic print (165 degree, not 162)

[edit] Steering

- 1. Mount block on foot do not allow full actuator movement

- 2. Mount of Firgelli too sloppy, maybe a plastic adaptor in each end?

- 1. Mount block in foot end has too small screws, and may be too week.

[edit] Knee

[edit] Hip

[edit] Main body

[edit] Electronics

[edit] Power

- Main power 6-cell LiPo nominel 22.2V (between 20V and 28.5V)

[edit] Teensy

- Teensy 3.2 and Teensy 3.5 for (first level) real time control loops

[edit] Main PC

- Look at a Intel Nuc

[edit] Sensors

[edit] Matlab Model

[edit] Software

[edit] Communication

- Losing IMU i2c communication at knee