Robobot hardware

(→Hardware) |

|||

| (17 intermediate revisions by one user not shown) | |||

| Line 6: | Line 6: | ||

All 3D-printed parts are designed in Onshape and are public. | All 3D-printed parts are designed in Onshape and are public. | ||

| − | They can be | + | They can be accessed at |

https://cad.onshape.com/documents/fef8699fcafb8aea780c8981/w/ce38e7fdd6cf8533b65e2c3c/e/eefdcf481faf2a4b03f5058c | https://cad.onshape.com/documents/fef8699fcafb8aea780c8981/w/ce38e7fdd6cf8533b65e2c3c/e/eefdcf481faf2a4b03f5058c | ||

| + | A browser-only CAD tool. | ||

For students, a free account can be created at https://www.onshape.com/en/education/ | For students, a free account can be created at https://www.onshape.com/en/education/ | ||

| − | ==Mounting holes== | + | All items can be exported (in e.g. step format) for import in other CAD tools. |

| + | |||

| + | ==Screws== | ||

| + | |||

| + | ===Mounting holes=== | ||

The hardware is 3D-printed plastic (except for the electronics and screws) | The hardware is 3D-printed plastic (except for the electronics and screws) | ||

| Line 19: | Line 24: | ||

* Hole diameter of 2.5mm, intended for 3mm plastic screws. | * Hole diameter of 2.5mm, intended for 3mm plastic screws. | ||

* Plastic thickness is 6mm in most cases. | * Plastic thickness is 6mm in most cases. | ||

| − | |||

| − | |||

===Screws for plastic (PT screws)=== | ===Screws for plastic (PT screws)=== | ||

| Line 27: | Line 30: | ||

Plastic (PT) screws: | Plastic (PT) screws: | ||

| − | * Cut into the plastic with a sharp | + | * Cut into the plastic with a sharp thread. |

* Gets locked into the plastic. | * Gets locked into the plastic. | ||

| Line 39: | Line 42: | ||

[[File:PT-screw.png | 300px]] | [[File:PT-screw.png | 300px]] | ||

| − | + | A typical pan head screw for thermoplastic. | |

===Screws for metal=== | ===Screws for metal=== | ||

| Line 47: | Line 50: | ||

Metal screw selection: | Metal screw selection: | ||

| − | * M3 pan head (servo horn 16mm, Torx TX10) | + | * M3 pan head (For servo horn, 16mm, Torx TX10) |

| − | * M3 countersunk (motor mount 12mm, Torx TX10) | + | * M3 countersunk (For motor mount, 12mm, Torx TX10) |

| − | * M5 bolt (For the main wheel | + | * M5 bolt (For the main wheel fastener, 16mm, Hex/Umbraco 4mm) |

| − | * M5 nut (For the main wheel | + | * M5 nut (For the main wheel fastener). |

* M6 bolt (Castor axles, length 50mm, Hex/Umbraco 5mm) | * M6 bolt (Castor axles, length 50mm, Hex/Umbraco 5mm) | ||

| + | |||

| + | ==Axles== | ||

| + | |||

| + | Castor wheel axles are made from | ||

| + | * 2mm piano wire, length 25mm (e.g.: https://www.hobbydirect.dk/shop/modelskibe-af-trae/tilbehoer/piano-traad-pianotraad.htm). | ||

| + | NB! This is hardened steel and can not be cut by normal cutting tools, use e.g. a Dremel cutting disk. | ||

| + | * 6mm bearing flange for castor, IGUS iglidur M250 flange bearing MFM061010 | ||

| + | |||

| + | ==Camera== | ||

| + | |||

| + | The used camera is a 'Jieli Technology' camera of type 'USB PHY 2.0' (packed by Sandberg as 'USB Webcam 1080P'). | ||

| + | |||

| + | The camera has limited control capabilities but supports the following data formats. | ||

| + | |||

| + | * MJPG coded 640 x 320 pixels at 25 or 30 FPS | ||

| + | * MJPG coded 1280 x 720 pixels at 25 or 30 FPS | ||

| + | * MJPG coded 1920 x 1080 pixels at 25 or 30 FPS | ||

| + | * MJPG coded 640 x 480 pixels at 25 or 30 FPS; this mode cuts parts of the image width to fit the format | ||

| + | |||

| + | It also supports "raw" format as YUYV 4:2:2, but it seems like data loss occurs (fragmented images), so do not use this format. | ||

| + | |||

| + | ==Servo== | ||

| + | |||

| + | The used servo is | ||

| + | * Savox SA-1230SG https://savox-servo.com/en/product/SA-1230SGplus/savox-servo-sa-1230sg-digital-coreless-motor-steel-gear | ||

| + | |||

| + | ==Distance sensor== | ||

| + | |||

| + | For distance measurement is used | ||

| + | * Sharp 2Y0A21 (7-80cm) https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiHpKfkgJGDAxX2h_0HHXSFCHIQFnoECBIQAQ&url=https%3A%2F%2Fglobal.sharp%2Fproducts%2Fdevice%2Flineup%2Fdata%2Fpdf%2Fdatasheet%2Fgp2y0a21yk_e.pdf&usg=AOvVaw2UFFgiLXC0mH_S1Q3VeqdZ&opi=89978449 | ||

| + | |||

| + | == Motor == | ||

| + | |||

| + | The motor is CHP-36GP-555 from https://www.airsoftmotor.com/encoder-motor/planetary-reducer-with-encoder/micro-dc-planetary-gear-motor-with-encoder.html | ||

| + | |||

| + | 12V with gearing 19:1 | ||

| + | |||

| + | Encoder with 17 magnets, i.e. 68 pulses per revolution. | ||

Latest revision as of 14:40, 4 January 2024

Back to Robobot B

Contents |

[edit] Hardware

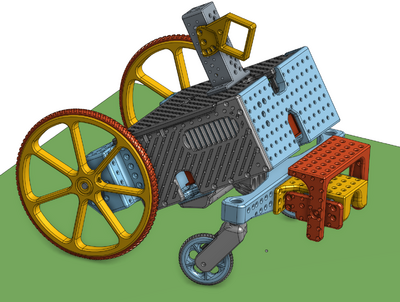

All 3D-printed parts are designed in Onshape and are public. They can be accessed at https://cad.onshape.com/documents/fef8699fcafb8aea780c8981/w/ce38e7fdd6cf8533b65e2c3c/e/eefdcf481faf2a4b03f5058c A browser-only CAD tool.

For students, a free account can be created at https://www.onshape.com/en/education/

All items can be exported (in e.g. step format) for import in other CAD tools.

[edit] Screws

[edit] Mounting holes

The hardware is 3D-printed plastic (except for the electronics and screws)

All 3D printed parts have holes for mounting additional parts. These holes have:

- Individual hole distance of 1cm.

- Hole diameter of 2.5mm, intended for 3mm plastic screws.

- Plastic thickness is 6mm in most cases.

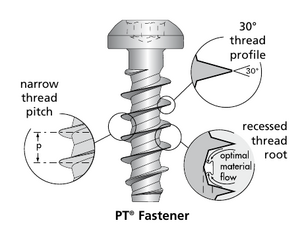

[edit] Screws for plastic (PT screws)

Mounting items on the 3D-printed thermoplastic should use plastic (PT) screws.

Plastic (PT) screws:

- Cut into the plastic with a sharp thread.

- Gets locked into the plastic.

Plastic (PT) screw selection:

- Pan-head 2.5mm for PCB mounting, length 8mm, Torx 8IP/TX8.

- Countersunk 3mm length 10mm, TX8, for the most plastic-plastic mount, where head height is important.

- Pan head 3mm, length 10mm, TX10, for the most plastic-plastic mount, with space for the head.

- Pan head 3mm, length 16mm, TX10, for servo arm 'axle'.

- Countersunk 3mm, length 25mm, TX8, box lit 'bearing' and camera mount.

A typical pan head screw for thermoplastic.

[edit] Screws for metal

Mounting of motors and other metal parts should use screws for metal.

Metal screw selection:

- M3 pan head (For servo horn, 16mm, Torx TX10)

- M3 countersunk (For motor mount, 12mm, Torx TX10)

- M5 bolt (For the main wheel fastener, 16mm, Hex/Umbraco 4mm)

- M5 nut (For the main wheel fastener).

- M6 bolt (Castor axles, length 50mm, Hex/Umbraco 5mm)

[edit] Axles

Castor wheel axles are made from

- 2mm piano wire, length 25mm (e.g.: https://www.hobbydirect.dk/shop/modelskibe-af-trae/tilbehoer/piano-traad-pianotraad.htm).

NB! This is hardened steel and can not be cut by normal cutting tools, use e.g. a Dremel cutting disk.

- 6mm bearing flange for castor, IGUS iglidur M250 flange bearing MFM061010

[edit] Camera

The used camera is a 'Jieli Technology' camera of type 'USB PHY 2.0' (packed by Sandberg as 'USB Webcam 1080P').

The camera has limited control capabilities but supports the following data formats.

- MJPG coded 640 x 320 pixels at 25 or 30 FPS

- MJPG coded 1280 x 720 pixels at 25 or 30 FPS

- MJPG coded 1920 x 1080 pixels at 25 or 30 FPS

- MJPG coded 640 x 480 pixels at 25 or 30 FPS; this mode cuts parts of the image width to fit the format

It also supports "raw" format as YUYV 4:2:2, but it seems like data loss occurs (fragmented images), so do not use this format.

[edit] Servo

The used servo is

- Savox SA-1230SG https://savox-servo.com/en/product/SA-1230SGplus/savox-servo-sa-1230sg-digital-coreless-motor-steel-gear

[edit] Distance sensor

For distance measurement is used

[edit] Motor

The motor is CHP-36GP-555 from https://www.airsoftmotor.com/encoder-motor/planetary-reducer-with-encoder/micro-dc-planetary-gear-motor-with-encoder.html

12V with gearing 19:1

Encoder with 17 magnets, i.e. 68 pulses per revolution.