PCB

(→Teensy board and schematic) |

|||

| (31 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| − | Flexbot PCBs | + | Back to [[Flexbot]] main page |

| + | |||

| + | =Flexbot PCBs= | ||

==Teensy board== | ==Teensy board== | ||

| − | [[File:leg_teensy_annotated.png]] | + | [[File:leg_teensy_annotated.png |700px]] |

Figure 1. Plug names and pin allocation for Teensy board. | Figure 1. Plug names and pin allocation for Teensy board. | ||

| + | * IMU0, on-board, SCL0, pin 18-19, AD0=NC, Knee. | ||

| + | * IMU1, SCL1, pin 37_38, AD0=HIGH (pin 27), Thigh (upper leg). | ||

| + | * IMU2, SCL1, pin 37_38, AD0=NC, Shin (lower leg). | ||

| + | * IMU3, SCL2, pin 3_4, AD0 = HIGH (pin 28), Foot. | ||

| + | * IMU4, SCL2, pin 3_4, AD0 = NC, Hip. | ||

| − | + | ===Actuators=== | |

| + | ====Steering==== | ||

| + | * 1: 12V, | ||

| + | * 2: PWM pin 5 - moved to pin 29 (timer FTM2 200 Hz?), Patch on rev A2, clean in rev B | ||

| + | * 3:pot pin 23 (A9), | ||

| + | * 4: GND | ||

| − | Figure 2. Functional blockdiagram og Teensy controller board. Not all blocks and MAV messages are implemented yet. | + | ====Actuator 1 - upper leg==== |

| + | motor | ||

| + | * 1: (5V) nc. | ||

| + | * 2: PWM pin 21 (timer FMT3) | ||

| + | * 3: direction pin 26 | ||

| + | * 4: GND | ||

| + | encoder | ||

| + | * 1: 5V | ||

| + | * 2: A pin 39 | ||

| + | * 3: B pin 30 - patched from A21 DAC0 on rev A2, clean on rev B | ||

| + | * 4: GND | ||

| + | current sensor | ||

| + | * 1: 5V | ||

| + | * 2: sense pin 16 (A2) | ||

| + | * 3: gnd | ||

| + | |||

| + | ====Actuator 2 - lower leg==== | ||

| + | Motor | ||

| + | * 1: direction pin 25 | ||

| + | * 2: PWM pin 22 (timer FMT0) | ||

| + | * 3: GND | ||

| + | encoder | ||

| + | * 1: 5V | ||

| + | * 2: A pin 5 - patched from A22/DAC1 on rev A2, clean on rev B | ||

| + | * 3: B pin 36 | ||

| + | * 4: GND | ||

| + | current sensor | ||

| + | * 1: 5V | ||

| + | * 2: sense pin 15 (A1) | ||

| + | * 3: gnd | ||

| + | |||

| + | ====Wheel==== | ||

| + | motor driver | ||

| + | * 1: nc (not connected on rev B, must not be connected on rev A2 (+5V source both ends)) | ||

| + | * 2: PWM pin 2 (timer FTM3) (S1) (RC mode 200 Hz?) | ||

| + | * 3: GND - NB! connected to motor power GND (probably OK to connect) | ||

| + | encoder | ||

| + | * 1: 5V | ||

| + | * 2: A pin 35 | ||

| + | * 3: B pin 34 | ||

| + | * 4: GND | ||

| + | current | ||

| + | * 1: 5V | ||

| + | * 2: sense pin 17 (A3) | ||

| + | * 3: GND | ||

| + | |||

| + | ==Cables in leg== | ||

| + | |||

| + | [[File:cables-in-leg.png |700px]] | ||

| + | |||

| + | Figure 2. Overview of cables in one leg with some wire details. The connection to robot base platform is 24V (10A) and USB only. | ||

| + | Steering servo should be in RC servo interface mode. | ||

| + | |||

| + | Wheel motor driver in RC mode: switch 1=off, all others ON. S1 used only. | ||

| + | |||

| + | ==Controller block diagram== | ||

| + | |||

| + | |||

| + | [[File:leg_teensy-block-function.png | 700px]] | ||

| + | |||

| + | Figure 3. Functional blockdiagram og Teensy controller board. Not all blocks and MAV messages are implemented yet. | ||

| + | |||

| + | ==Teensy board and schematic== | ||

| + | |||

| + | [[File:leg_teensy_board.png | 600px]] | ||

| + | |||

| + | Figure 4. Layout of PCB revision A2 (designed in Eagle). | ||

| − | |||

| − | |||

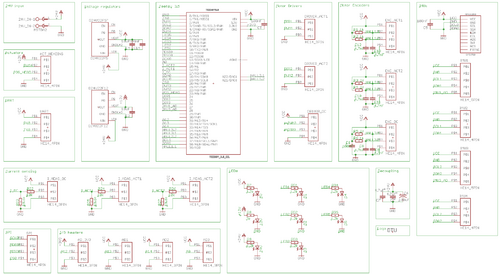

[[File:leg_teensy_schematic.png | 500px]] | [[File:leg_teensy_schematic.png | 500px]] | ||

| − | Figure | + | Figure 5. PCB schematic revision A2 - click on image to get better view. |

| + | |||

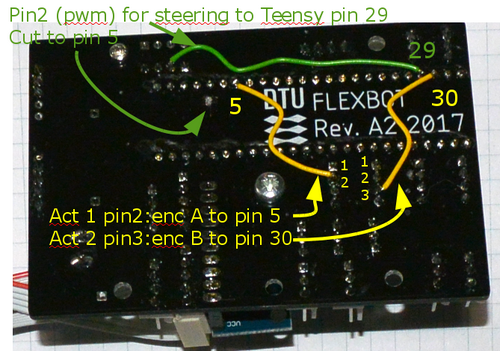

| + | [[File:teensy_board_patches_annotated.png | 500px]] | ||

| + | |||

| + | Figure 6. Needed patches from version A2 to revision B. PWM for steering servo in RC mode now moved to timer FMT3 on pin 29 (old connection to pin 5 must be cut). Actuator 2 encoder A also connected to pin 5 (for interrupt), and actuator 1 encoder B also connected to (free) pin 30 - also for interrupt (annotated image has error Act 1<->2). The last 2 maintains connection to DAC pins and pull-up resistors. | ||

| + | |||

| + | |||

| + | ---- | ||

| + | --[[User:Jca|Jca]] ([[User talk:Jca|talk]]) 13:03, 9 June 2018 (CEST) | ||

Latest revision as of 17:28, 27 October 2018

Back to Flexbot main page

Contents |

[edit] Flexbot PCBs

[edit] Teensy board

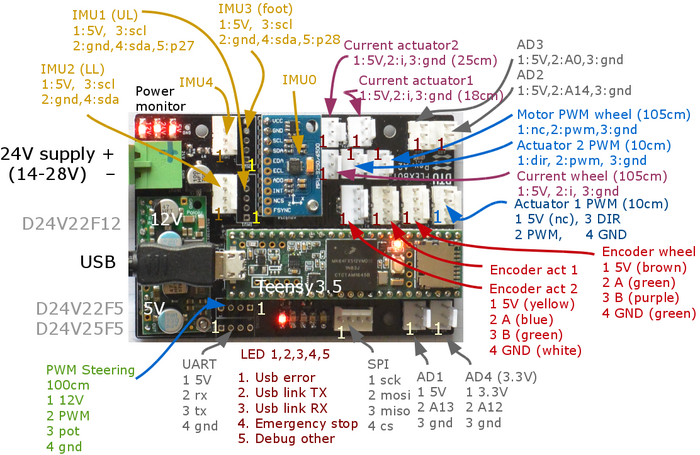

Figure 1. Plug names and pin allocation for Teensy board.

- IMU0, on-board, SCL0, pin 18-19, AD0=NC, Knee.

- IMU1, SCL1, pin 37_38, AD0=HIGH (pin 27), Thigh (upper leg).

- IMU2, SCL1, pin 37_38, AD0=NC, Shin (lower leg).

- IMU3, SCL2, pin 3_4, AD0 = HIGH (pin 28), Foot.

- IMU4, SCL2, pin 3_4, AD0 = NC, Hip.

[edit] Actuators

[edit] Steering

- 1: 12V,

- 2: PWM pin 5 - moved to pin 29 (timer FTM2 200 Hz?), Patch on rev A2, clean in rev B

- 3:pot pin 23 (A9),

- 4: GND

[edit] Actuator 1 - upper leg

motor

- 1: (5V) nc.

- 2: PWM pin 21 (timer FMT3)

- 3: direction pin 26

- 4: GND

encoder

- 1: 5V

- 2: A pin 39

- 3: B pin 30 - patched from A21 DAC0 on rev A2, clean on rev B

- 4: GND

current sensor

- 1: 5V

- 2: sense pin 16 (A2)

- 3: gnd

[edit] Actuator 2 - lower leg

Motor

- 1: direction pin 25

- 2: PWM pin 22 (timer FMT0)

- 3: GND

encoder

- 1: 5V

- 2: A pin 5 - patched from A22/DAC1 on rev A2, clean on rev B

- 3: B pin 36

- 4: GND

current sensor

- 1: 5V

- 2: sense pin 15 (A1)

- 3: gnd

[edit] Wheel

motor driver

- 1: nc (not connected on rev B, must not be connected on rev A2 (+5V source both ends))

- 2: PWM pin 2 (timer FTM3) (S1) (RC mode 200 Hz?)

- 3: GND - NB! connected to motor power GND (probably OK to connect)

encoder

- 1: 5V

- 2: A pin 35

- 3: B pin 34

- 4: GND

current

- 1: 5V

- 2: sense pin 17 (A3)

- 3: GND

[edit] Cables in leg

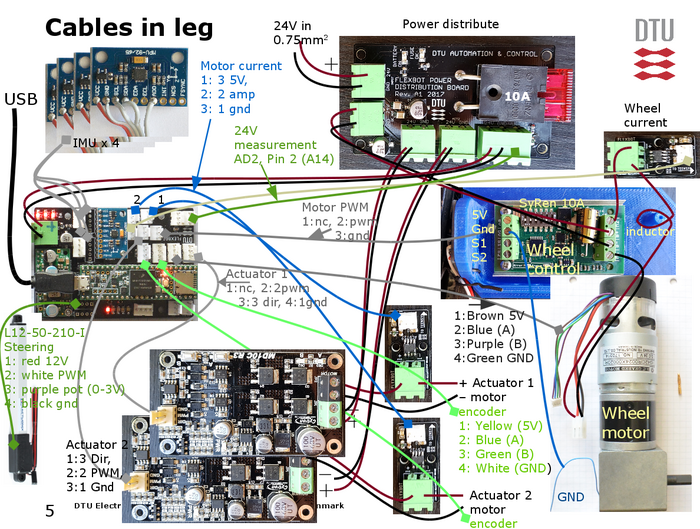

Figure 2. Overview of cables in one leg with some wire details. The connection to robot base platform is 24V (10A) and USB only. Steering servo should be in RC servo interface mode.

Wheel motor driver in RC mode: switch 1=off, all others ON. S1 used only.

[edit] Controller block diagram

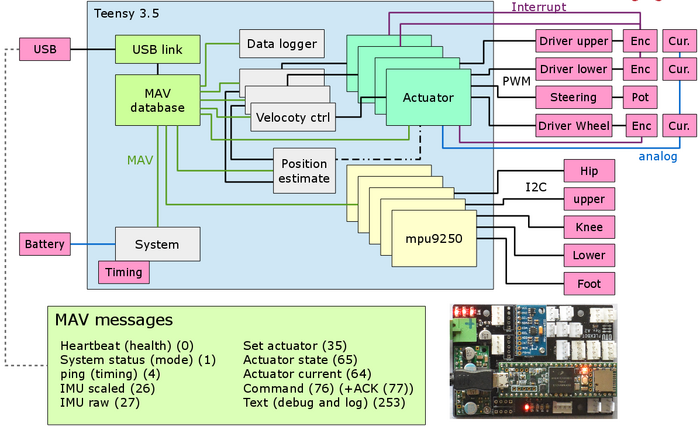

Figure 3. Functional blockdiagram og Teensy controller board. Not all blocks and MAV messages are implemented yet.

[edit] Teensy board and schematic

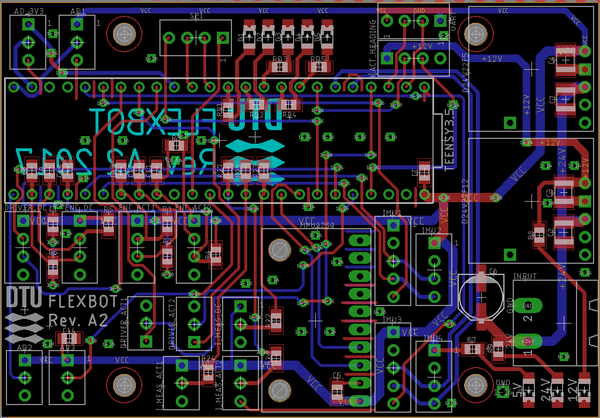

Figure 4. Layout of PCB revision A2 (designed in Eagle).

Figure 5. PCB schematic revision A2 - click on image to get better view.

Figure 6. Needed patches from version A2 to revision B. PWM for steering servo in RC mode now moved to timer FMT3 on pin 29 (old connection to pin 5 must be cut). Actuator 2 encoder A also connected to pin 5 (for interrupt), and actuator 1 encoder B also connected to (free) pin 30 - also for interrupt (annotated image has error Act 1<->2). The last 2 maintains connection to DAC pins and pull-up resistors.