Getting started

(→Battery maintenance) |

|||

| Line 15: | Line 15: | ||

'''NB2!''' Connecting the charger, or connecting USB cable while charging, sometimes disturb the processor on REGBOT. Especially if the PC is also connected to 230V. | '''NB2!''' Connecting the charger, or connecting USB cable while charging, sometimes disturb the processor on REGBOT. Especially if the PC is also connected to 230V. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Connect== | ==Connect== | ||

| Line 34: | Line 22: | ||

[[File:screenshot-regbot.png | 800px]] | [[File:screenshot-regbot.png | 800px]] | ||

| − | Figure 1. REGBOT GUI, then top-left frame controls the connection. | + | Figure 1. REGBOT GUI, then top-left frame controls the connection. Either communication over an USB com-port (recommended) or using WiFi (poor performance). |

===USB=== | ===USB=== | ||

| − | Connect USB cable and figure out which COM port is created for the robot (NB! each robot connected to the PC has probably reserved a COM-port number) | + | Connect USB cable and figure out which COM port is created for the robot (NB! each robot connected to the PC has probably reserved a COM-port number). |

In figure 1 the robot has created COM6:. | In figure 1 the robot has created COM6:. | ||

| Line 57: | Line 45: | ||

When connected over USB, the IP of the robot will be in the wifi tab (use menu "show" if not visible). | When connected over USB, the IP of the robot will be in the wifi tab (use menu "show" if not visible). | ||

| + | |||

| + | NB! wifi has low performance! | ||

===Status=== | ===Status=== | ||

Revision as of 16:22, 12 January 2021

Back to Regbot main page.

Contents |

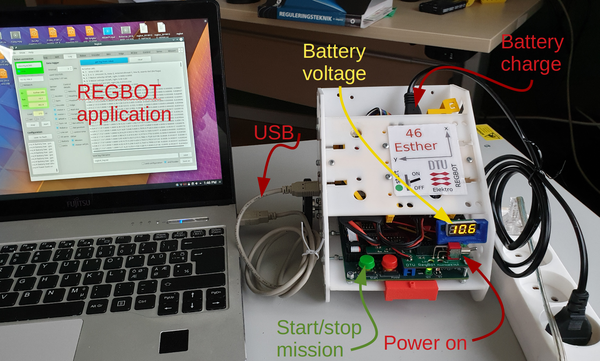

The robot

The robot can connect to a PC using USB (or Wifi), but start with USB.

Battery maintenance

The battery is nominal 11.1V (3 LiPo cells) and the robot shuts down if below 10V.

NB! the charger cable to the battery (4-wire balance plug) is disconnected on some robots. See Regbot maintenance for more details.

NB2! Connecting the charger, or connecting USB cable while charging, sometimes disturb the processor on REGBOT. Especially if the PC is also connected to 230V.

Connect

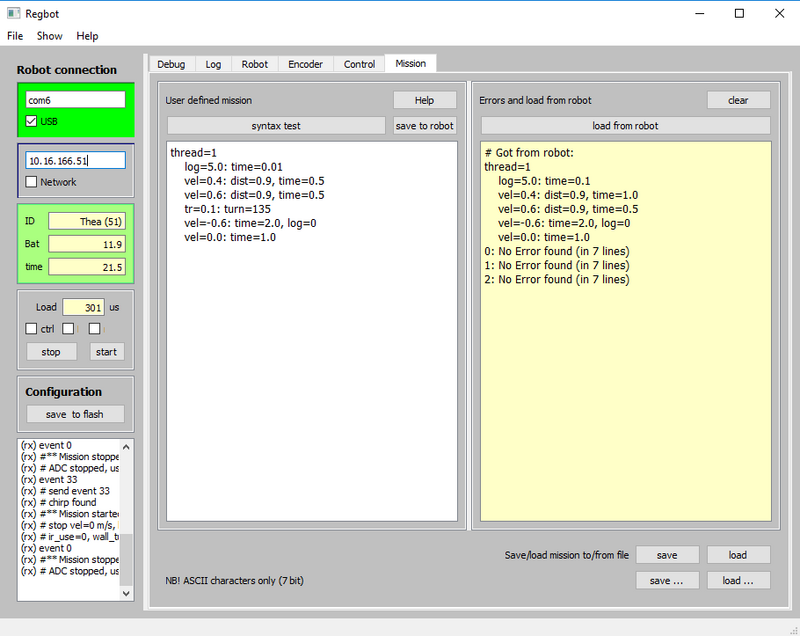

The GUI looks like shown here in figure 1.

Figure 1. REGBOT GUI, then top-left frame controls the connection. Either communication over an USB com-port (recommended) or using WiFi (poor performance).

USB

Connect USB cable and figure out which COM port is created for the robot (NB! each robot connected to the PC has probably reserved a COM-port number).

In figure 1 the robot has created COM6:.

USB is much faster than wifi, especially when downloading a log.

WiFi

At DTU the robots attempt to connect to the DEVICE WiFi access point (SSID=device), it may take 20 seconds to establish the connection.

Each robot has a reserved IP:

10.16.166.XXX

Where XXX is the robot number. The robot Thea has number 51, so its IP number is 10.16.166.51.

A number of remarks and debug messages (shown in the lower-left frame in figure 1) will not be sent over WiFi (lower bandwidth).

When connected over USB, the IP of the robot will be in the wifi tab (use menu "show" if not visible).

NB! wifi has low performance!

Status

Once connected the robot time and name is shown in a green frame (figure 1). Below the green frame is a frame to start and stop missions. The start button is a replication of the green button on the robot.

The "Load" field shows how much time the robot uses for every sample (the robot samples all sensors and calculations every 1ms), so the load should be less than 1000us at all times.

When the configuration or mission is changed it can be saved to a small flash disk (2kB) on the robot with the "save to flash" button.

Menu

The menus has some extra features.

Help

Most fields has explanations, when the mouse hoovers over the field.

User interface

More details on user interface on User_interface

More details on missions on Mission

Control configuration

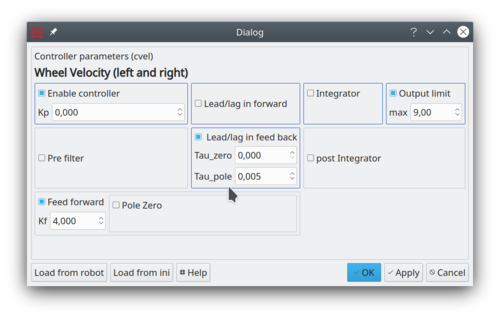

This is a control exercise robot, so some control must be configured to run missions.

Control is configured from the control tab - see also User_interface#Controller_configuration.

The velocity control is the most important, and in the dialogue shown below in figure 2, set the values in the figure text (NOT as the screenshot).

Figure 2. Set Kp = 0, but enabled. Set "Feed forward" Kf = 4. Set output limit to 9V and disable the "Lead/lag in feedback" and all other settings. This will translate a mission velocity of 0.5 m/s by a factor 4 to a motor voltage of 2 Volt, which in turn approximately gives a velocity of 0.5 m/s.