Drone motor performance

(Created page with "Back to Drone control ==Motor and propeller performance== Measured with the "motortest" firmware and the python app below. The used motor is the 3508-700KV Turnigy Mult...") |

Revision as of 08:10, 10 October 2020

Back to Drone control

Contents |

Motor and propeller performance

Measured with the "motortest" firmware and the python app below. The used motor is the 3508-700KV Turnigy Multistar 14 Pole Brushless and a 14x5.5 carbon propeller. The ESC is a Hobby-wing x-rotor 40A controller.

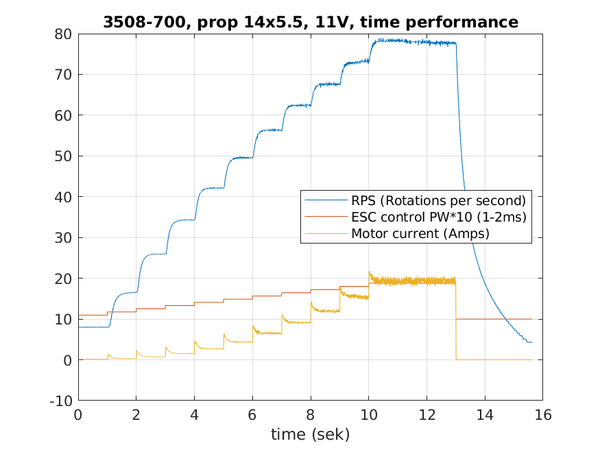

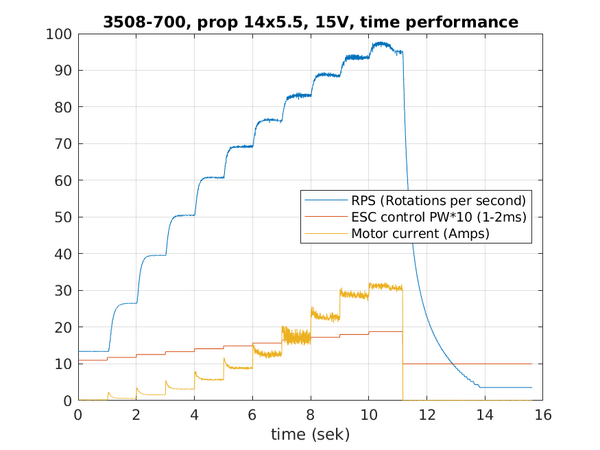

Time responce

With 11 V supply (left) and 15V (right).

From 1.1ms to the ESC (idle) to 1.9ms almost full throttle. The ESC update frequency is 400 Hz.

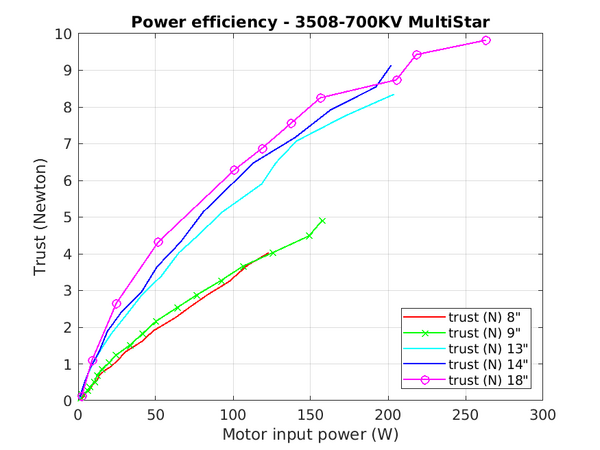

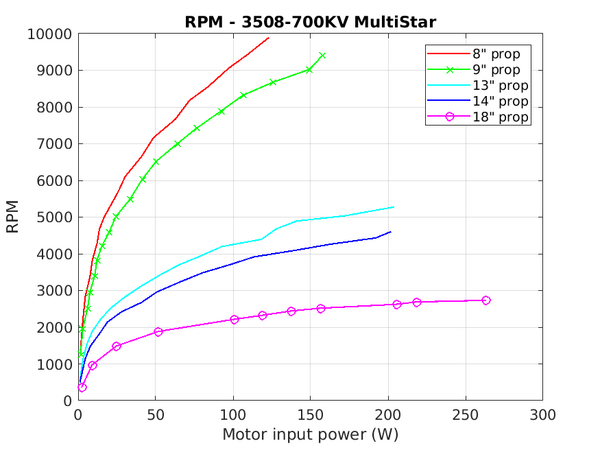

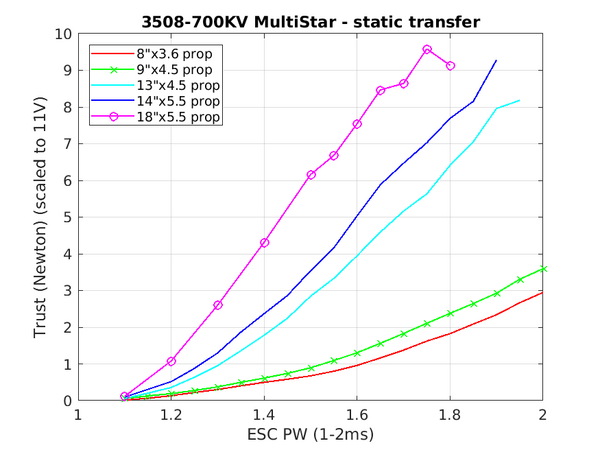

Static response 3508-700

Transfer measurement with different propellers. The Hobby Wing controller is calibrated to 1ms=off, 2ms=full power. Measurement is in a fixed setup on a scale with 1g resolution. Propeller 50cm above ground level. Power is a lab power supply. Motor and ESC temperature below 50 degree C.

The propellers

- 8"x 3.8 APC composite propeller

- 9"x 4.5 APC composite propeller

- 13"x 4.5 carbon fiber

- 14"x 5.5 carbon fiber

- 18"x 5.5 carbon fiber Quanum

(Left) trust delivered for each propeller size as a function of motor input power. It shows that bigger propellers are more power-efficient. (Right) RPM as a function of input power.

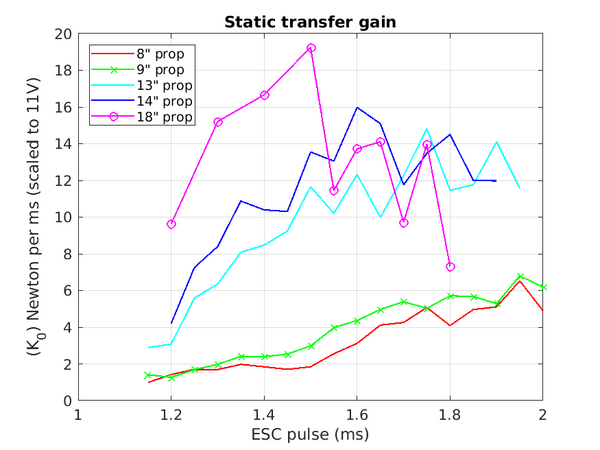

Static gain 3508-700

For the same data as above, bot now related to the ESC input pulse width. The ESC has been calibrated to 1ms is zero power, 2ms is maximum power. All data has been scaler to 11V, as the curves scale almost 1:1 with the input voltage.

(Left) Trust curve as a function of ESC pulse width. Bigger propellers require more power but deliver more trust. (Right) Static transfer gain as a function of ESC pulse width. The transfer gain is fairly constant (within a factor 2) in the useful trust area.